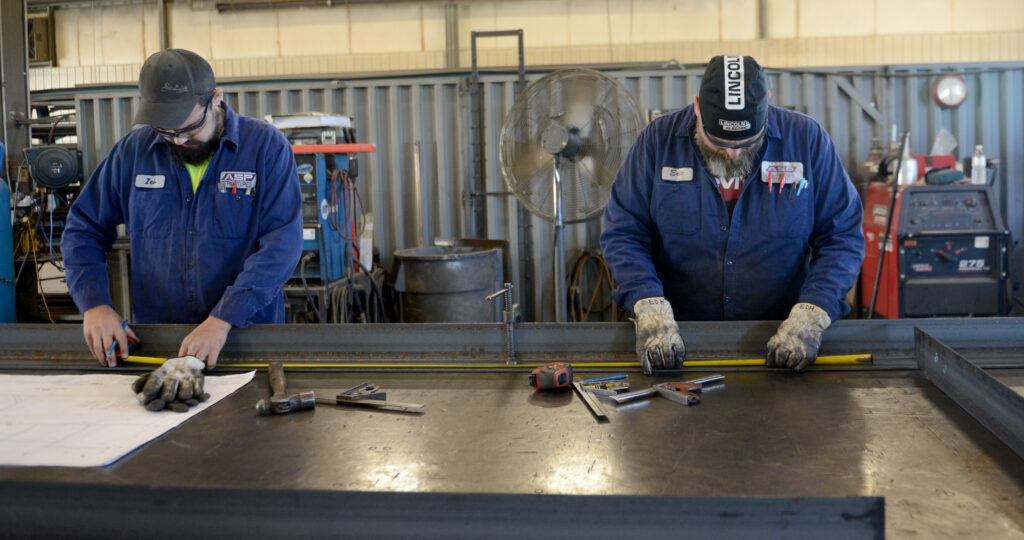

Structural Steel Fabrication

ASP is an AISC-quality certified building fabricator providing structural and access steel fabrication and erection services across the mid-Atlantic.

We use CNC equipment to fabricate all types of structural steel from beams and columns to trusses and complex frames.

In addition to fabricating from carbon steel, stainless steel, and aluminum, we furnish necessary items such as open-web steel joists, steel decking, fasteners, cold-formed light gauge sections, steel roofing, siding, and trim.

We offer painting and priming from our indoor paint facility. And we have trusted, local partners who perform galvanization, powder coating, and sandblasting services.

Our talented team utilizes a variety of state-of-the-art cutting, welding, drilling, and punching machines to bring your vision to life:

- Computer-operated drill machine

- Computer-operated angle punch and shear

- Overhead cranes

- Multiple torch plate burning machines

- Plate shears

- Numerous wire-feed welding machines

- Powered rollers

Learn more about the fabrication process.

If we do not believe that a structural steel building is the best fit for your project, we will recommend a local company who is the best fit.

Why Structural Steel?

> Cost Effective – As a framing material, structural steel yields a greater value in a project from both initial cost and reduced costs of foundations, general conditions, and facades.

> Accelerated schedule – Structural steel can be fabricated off-site while the site work and foundations are being completed. It is then delivered to the site and erected.

> Increased usable floor space – It is light and strong, which allows for long spans and open, column-free space.

> Aesthetically pleasing – Structural steel frames have a wide range of options, it can be rolled, curved and integrated into irregular building shapes.

> Future adaptability – An existing steel frame can be modified to address changing building requirements and uses.

> Quality and predictability – Fabrication takes place off-site in controlled conditions, ensuring a high-quality product.

> Environmentally friendly – Modern steel mills can produce steel containing up to 90 percent recycled material. At the end of a building’s life cycle, 100 percent of the steel frame can be recycled. This equates to low environmental impacts on a per-square-foot of construction basis.

> Malleability – No matter what project you are working on or what challenges arise, there is always a solution in steel.

Ready to start your project?